Submersible Mixers Description

The use of propellers for hydraulic circulation is an efficient and energy-saving means, especially widely used in anaerobic ponds, anoxic ponds and oxidation ditch in sewage biochemical treatment. Since only the necessary circulation and flow rate need to be provided in this type of pond, the mixed liquid in the pond can be kept in a suspended state, so that the microorganisms can be fully contacted with their substrates, so the pond shape mostly adopts the shape of an oxidation ditch, and the energy input through the propeller, A continuous circulating water flow is formed. This design can not only effectively maintain the suspension of the mixed liquid, but also because the flow rate of the circulating water flow in the pool is usually dozens or even hundreds of times higher than the flow rate of the influent water, so that the flow in the pool has a huge dilution and homogenization ability, thus making the process resistant to impact. load characteristics. Also in the design of the oxidation ditch, the surface exposure equipment has the dual functions of oxygenation and hydraulic circulation. In engineering, when it is often necessary to adjust the oxygenation capacity due to changes in water quality and water volume, it is difficult to take into account the circulating flow rate in the pool, resulting in the problem of sludge deposition in the ditch. Carrying out this technological transformation is not complicated, and the investment is very small.

Submersible Mixers Parameter

Model

Power (kW)

Current (A)

Rotary speed (rpm)

Impeller Diameter (mm)

Force (N)

Weight (kg)

SMB0.85/8-260/3-740/C/S

0.85

3.4

740

260

163

55/58

SMB1.5/6-260/3-980/C/S

1.5

4.4

980

260

290

55/58

SMB2.2/8-320/3-740/C/S

2.2

5.9

740

320

582

74/77

SMB4/6-320/3-980/C/S

4

10.8

980

320

609

74/77

SMB1.5/8-400/3-740/S

1.5

5.6

740

400

382

76/80

SMB2.5/8-400/3-740/S

2.5

7.3

740

400

575

76/80

SMB3/8-400/3-740/S

3

8.6

740

400

642

78/82

SMB4/6-400/3-980/S

4

10.3

980

400

1010

80/84

SMB4/12-620/3-480/S

4

14

480

620

1230

240/245

SMB5/12-620/3-480/S

5

18.2

480

620

1420

240/245

SMB7.5/12-620/3-480/S

7.5

28

480

620

1963

255/270

SMB10/12-620/3-480/S

10

32

480

620

2361

255/270

Submersible Mixers Factor

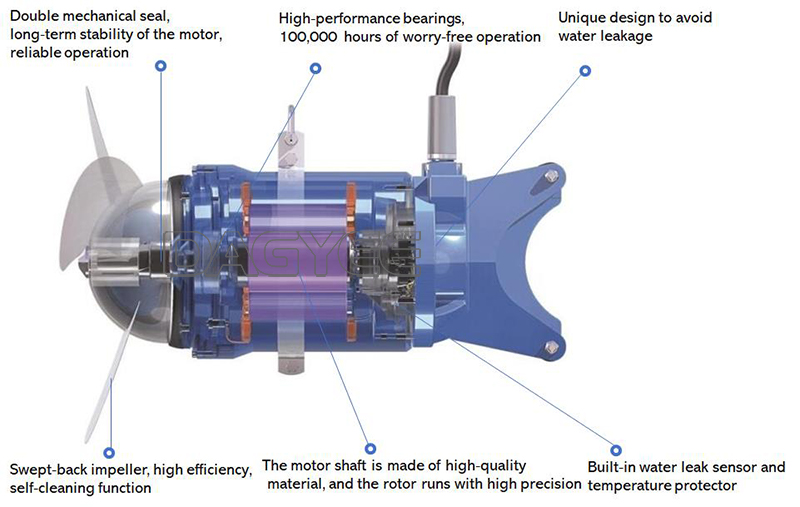

Submersible Mixers Features

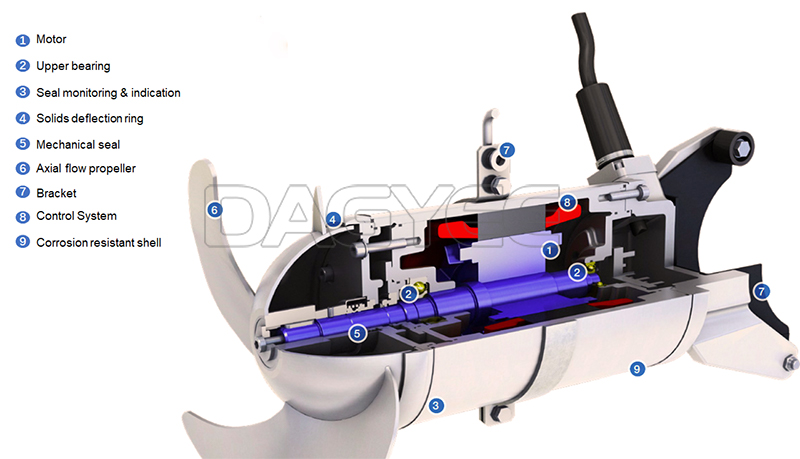

Submersible Mixers Component

|

Shell |

Stainless steel/GG25 cast iron |

|

Impeller |

Stainless steel/Fiberglass Polyurethane |

|

Shaft |

ASTM431 or 420 Stainless steel |

|

Mechanical seal |

Corrosion resistant cemented tungsten carbide/or silicon carbide |

|

Guide rod |

ASTN304 stainless steel |

|

Lifting Bracket |

ASTM304 Stainless Steel |

|

Lifting Cable |

ASTM304 Stainless Steel |

|

Fasteners |

ASTM321 Stainless Steel |

Submersible Mixers Application

Energy-saving Submersible Mixers Selection

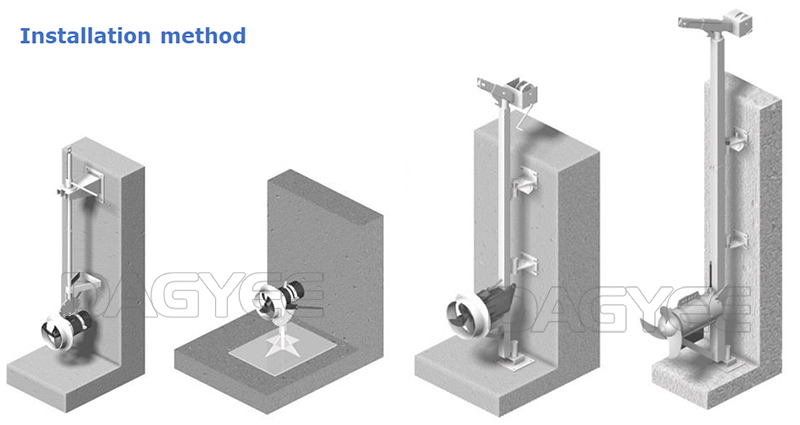

Submersible Mixers Installation Method

Name: Ashely Li

Mobile:+8613961861780

Tel:+8613961861780

Whatsapp:8613961861780

Email:info@dagyee.com

Add:Room 302, Building 11-4, Hongyi Road, Xinan Town, Xinwu District, jiangsu Province, China