Compact Units Pretreatment Plants For Wastewater Treatment Description

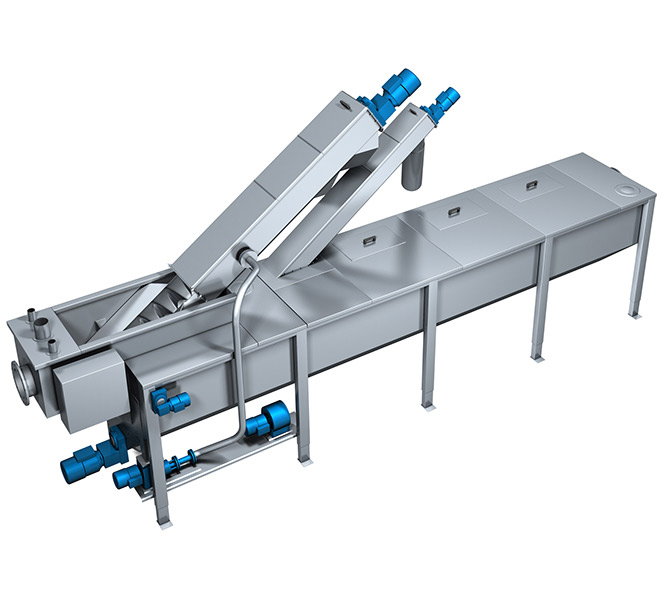

Combined pretreatment system is an answer to the high civil works costs and large footprint required to execute complete pretreatment systems in concrete, screening channel, sedimentation tanks and hoppers FOG removal. The DAGYEE system is a state-of-the-art combined pretreatment system designed to optimally perform all the effluent pretreatment function, screening, grit removal, FOG removal, in a single stainless steel machine.

The DAGYEE range consists of for screening and grit removal and the for screening, grit removal and FOG removal.

Generally supplied with the CFC Screw Screen, but in special execution it is also possible to provide it with the auger rotating drum screen, the step screen, the sub-Vertical bar Screen, or the perforated plate and brush screen.

Combined Screening Component

Dependable, complete and compact unit Performing the following process steps:

fine screening

Screenings dewatering

Grit separation

Grit dewatering

Grease separation and removal (optional)

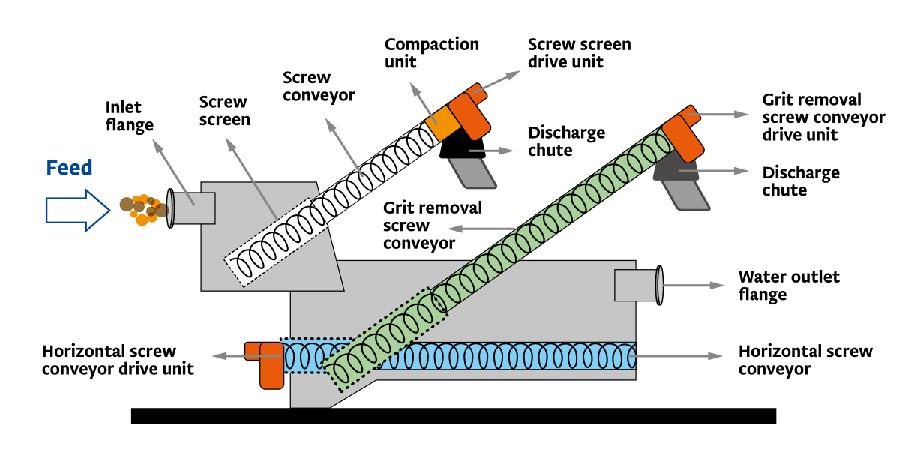

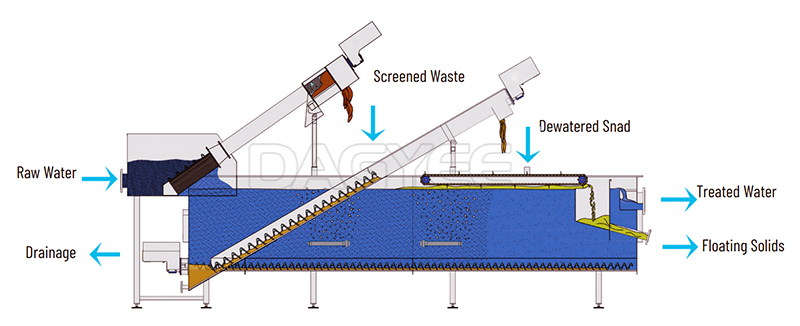

Combined Screening Working Principle

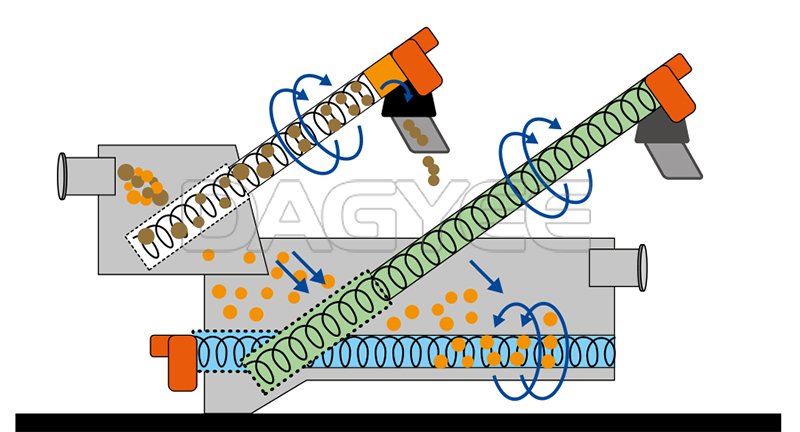

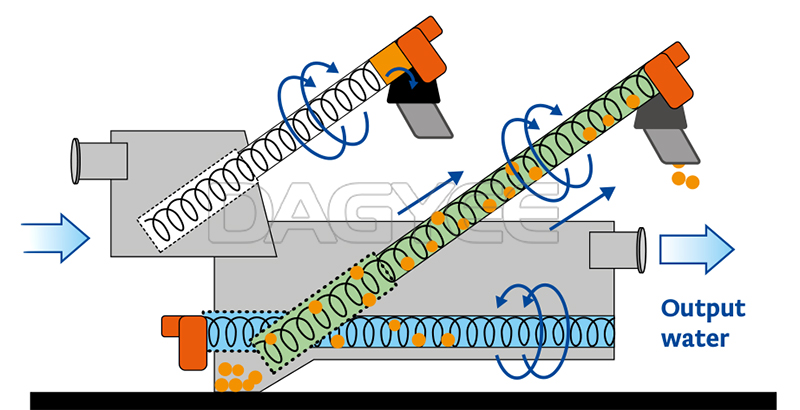

Combined unit for wastewater pretreatment Introduce sewage treatment plants. they perform Fine screening, grit removal and optional grease removal.Wastewater passes through spiral screen, solids Materials larger than the mesh size,The size is captured and removed from the system. they are compaction at the end of the screen conveyor before unloading.

The wastewater flows into the sedimentation tank. finer solid matter still present in wastewater Settled in a tank and conveyed to a hopper by a horizontal screw conveyor is placed at the bottom of the tank. OneInstallation of inclined screw conveyor for sand removal conveying the sand accumulated in the hopper,Drain into a container. filtered water leaves The system passes through an outlet tube placed on the upper level.Grease removal unit can be integrated into DAGYEE combination units are available upon request.

The wastewater firstly enters the tank where a screw screen is placed.

Big size solid materials are filtrated by the screw screen and a screw conveyor moves the solid materials captured up to the discharge point. At the end of the conveyor, they are pressed by the compaction unit before discharge.

The water which has still solid materials in smaller sizes flows through the sedimentation tank. The particles are settled by time and a horizontal screwconveyor transports them to the collection hopper.

Finally, they are conveyed by the grit removal screw conveyor to the discharge point.

Combined Screening Parameter

| Power Specifications | ||||||

| Model | Capacity (m3/h) | Tank Length(mm) | Tank Width(mm) | Inlet Flange DN | Outlet Flange DN | Max.Wash Water(L/S) |

| DSP-30 | 30 | 4200 | 1200 | DN200 | DN200 | 0.5 |

| DSP-50 | 50 | 5800 | 1200 | DN200 | DN200 | 0.5 |

| DSP-100 | 100 | 7000 | 1200 | DN250 | DN250 | 1 |

| DSP-150 | 150 | 7000 | 1200 | DN250 | DN250 | 1 |

| DSP-200 | 200 | 8000 | 1500 | DN300 | DN300 | 1 |

| DSP-250 | 250 | 8500 | 1500 | DN350 | DN350 | 1 |

| DSP-350 | 350 | 10000 | 1500 | DN400 | DN400 | 1 |

| DSP-400 | 400 | 12000 | 1800 | DN500 | DN500 | 1 |

| DSP-500 | 500 | 15000 | 2000 | DN500 | DN500 | 1 |

| Power Specifications | ||||

| Model | Screw Screen Power(kw) | Screw Conveyor Power(kw) |

Grit Removal

Power(kw)

|

Grease Removal

Power(kw)

|

| DSP-30 | 0.55 | 0.25 | 0.37 | 0.18 |

| DSP-50 | 0.55 | 0.35 | 0.37 | 0.18 |

| DSP-100 | 0.75 | 0.37 | 0.55 | 0.18 |

| DSP-150 | 0.75 | 0.37 | 0.55 | 0.18 |

| DSP-200 | 0.75 | 0.55 | 0.75 | 0.18 |

| DSP-250 | 1.1 | 0.55 | 0.75 | 0.18 |

| DSP-350 | 1.1 | 0.55 | 0.75 | 0.18 |

| DSP-400 | 1.1 | 0.55 | 0.75 | 0.18 |

| DSP-500 | 1.1 | 0.55 | 1..1 | 0.18 |

Combined Screening Features

Compact design

No odour or clogging problems

Low investment cost

Low maintenance and operation costs

No civil works required

Easy to install and operate

Volume reduction of the washed out solid

Low residual organic content in the washed out solid

Combined Screening Applications

Small sewage treatment works

Municipal wastewater treatment plants

Industrial wastewater treatment plant

Combined Screening Functions

Screening

Washing/compacting of solid removed

Sand/grit separation

Degreasing

Main advantages

Odor-free

No clogging

Low maintenance and operation costs

Low room needed

No construction works needed

Easy to install and operate

Very low residual organic content in the washed out solid

Volume reduction (up to 40%) of the washed out solid

Name: Ashely Li

Mobile:+8613961861780

Tel:+8613961861780

Whatsapp:8613961861780

Email:info@dagyee.com

Add:Room 302, Building 11-4, Hongyi Road, Xinan Town, Xinwu District, jiangsu Province, China