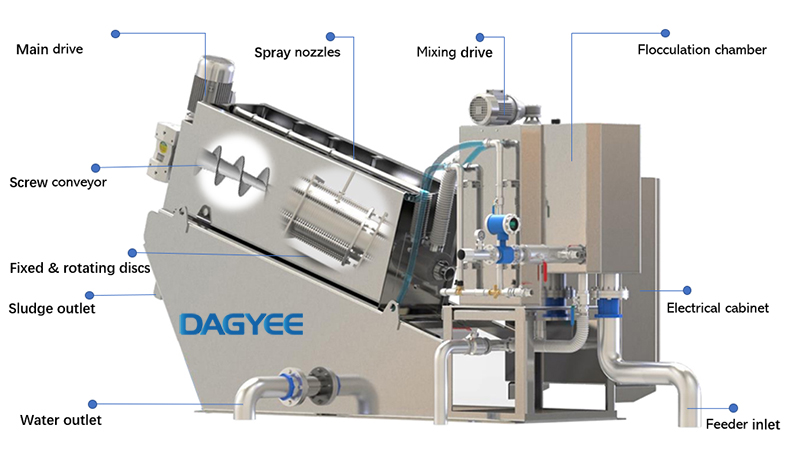

Sludge Dehydrator Description

Multidisc are arranged one after other with alternate disc being moving and fixed.The gap between the plates acts as media for fine filtration.The screw press main unit requires very very low power motor and the filtration surface area consists of a multiple discs which are self-cleaning, and generally do not clog, thus, the sludge press can be used continuously.

The main unit of the sludge dewatering screw press is of multi-shaft design. Hence, when two or more main units are configured into one machine, any individual shaft can be repaired or serviced without interrupting operations.

Sludge Dehydrator Process

Thickening: When the shaft is driven by the screw, moving rings around the shaft move up and down relatively. Most water is pressed out from the thickening zone and fall down to the filtrate tank for gravity;

Dewatering: The thickened sludge moves forward continuously from the thickening zone towards the dewatering zone. With the pitch of the screw shaft thread getting narrower and narrower, the pressure in the filter chamber increases higher and higher. In addition to the pressure generated by the back-pressure plate, the sludge is greatly pressed and dryer sludge cakes produce;

Self-cleaning: The moving rings rotates continuously up and down under the pushing of the running screw shaft while the gaps between the fixed rings and moving rings are cleaned to prevent from clogging that happens frequently for traditional dewatering equipment.

Sludge Dehydrator Model

Model

DL303

DS

capacity kg/h

90--150 kg/h

Sludge capacity m3/h(2-50g/L)

3-45

Spiral diameter mm

¢310*3

Discharge

Distance mm

495

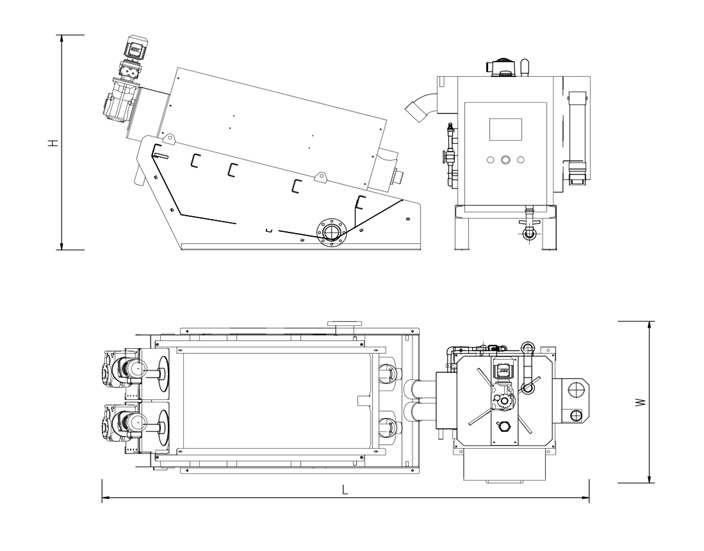

Size L*W*H

mm

3605*1690*1600

Net.Kg

1520

Run Kg

3080

Power

Kw

1.86

Washing Q L/h

120

Sludge Dehydrator Widely Use

Applicable sludge concentration of 2000mg/L-50000mg/L;

Most especially for the oily sludge;

Fully Automatic Control;

Combining with the auto control system, the machine runs very safely and simply and can be programmed according to the requirement of the users;

It can operate automatically for 24 hours, unmanned.

Sludge Dehydrator Features

Automatic continuous operation

Compact design with flocculation and dewatering

Low power and water consumption

Low operation cost

No filter cloth, no clogging

No need for sludge thickener

Easy operation and maintenance

No vibration and noise

Sludge Dehydrator Application

Simple arrangementSimple arrangement;

Low Power Consumption;

Simple and short start-up and shut down procedures;

Continuous operation. Hence continuous output can be obtained process can be automized;

Only electricity and water supply for cleaning is required, and that too in less amount;

For a multi-channel machine, one or more channels may be removed for maintenance purposes, while the machine with the remaining channels may still be operated;

No clogging. Cleaning is automized and is easy;

Long life of discs;

No external lubrication system is required;

Flocculator built in the Screw press.

Name: Ashely Li

Mobile:+8613961861780

Tel:+8613961861780

Whatsapp:8613961861780

Email:info@dagyee.com

Add:Room 302, Building 11-4, Hongyi Road, Xinan Town, Xinwu District, jiangsu Province, China