Shaftless Screw Conveyor Description

Shaftless Screw Conveyors are designed to handle almost any bulk material, from dry and free-flowing to sticky and sluggish. Shaftless screw conveyors are ideal for bulk materials with high moisture content that have a tendency to adhere to the center pipe of a conventional shafted screw conveyor.

After performance requirements and product characteristics are known, begins a systematic design process by applying proprietary calculations to determine conveyor size, rotational speed and horsepower to deliver the desired capacity. Due to the stresses associated with conveying sluggish and often abrasive bulk materials, high performance, heavy-duty materials of construction are integrated into a Shaftless Screw Conveyor system.

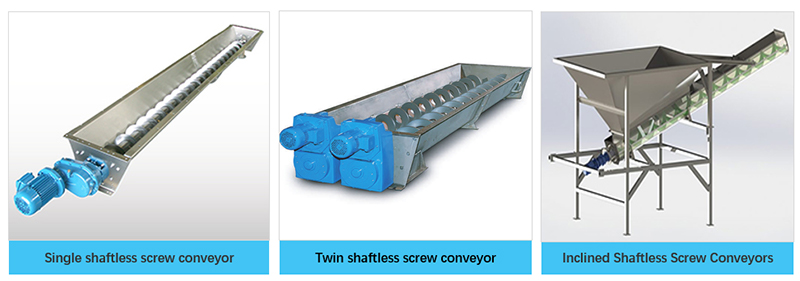

Shaftless Screw Conveyor Model

Single shaftless screw conveyor screw shaft, without mixing and stirring functions.

Twin Shaftless Screw Conveyor It adopts double screw blades with mixing and stirring functions. The two screw blades rotate in opposite directions to avoid material blocking. The conveying capacity is 1.5-2 times that of a single shaft.

Inclined Shaftless Screw Conveyor mainly used for conveying materials at a small angle of 25°.

|

DLS Model |

Capacities (m3/h) |

Length | Speed | Size | ||||

| 00 | 150 | 300 | (m) | (r/min) | A(mm) | B(mm) | B0(mm) | |

| DLS200 | 2 | 1.4 | 0.9 | 10 | 20 | 200 | 310 | 270 |

| DLS260 | 3.5 | 2.5 | 1.5 | 10 | 20 | 260 | 370 | 340 |

| DLS320 | 9 | 6.5 | 4.1 | 15 | 20 | 320 | 430 | 400 |

| DLS355 | 11.5 | 7.8 | 5.5 | 20 | 20 | 355 | 465 | 435 |

| DLS420 | 15 | 11 | 7.5 | 20 | 20 | 420 | 530 | 500 |

| DLS500 | 30 | 25 | 21 | 20 | 20 | 500 | 560 | 680 |

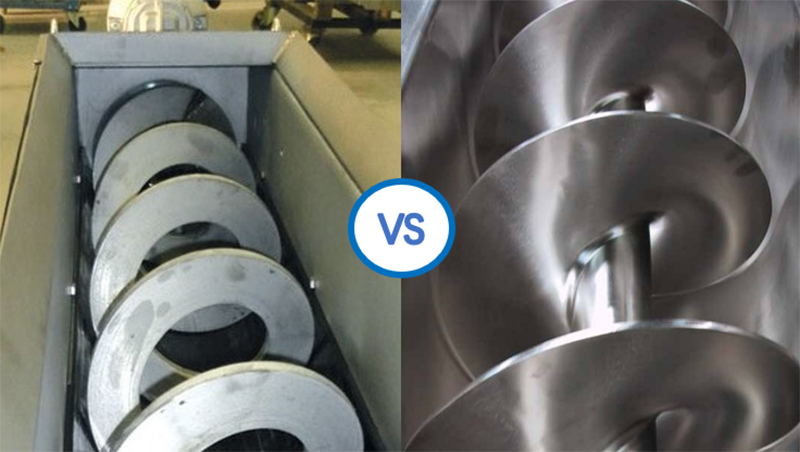

Shaftless Screw Conveyors VS Shafted Screw Conveyors

Conveying materials

Shaftless is suitable for conveying sludge, household garbage, grid slag and other viscous, entangled materials and massive materials. It is precisely because the design of the shaftless screw conveyor without a central axis has great advantages for these materials.

The shaft screw conveyor is suitable for conveying materials: powder, small particle materials, etc. If you convey viscous

materials such as sludge, it will stick to the inner tube shaft and blades, and the conveying block materials are easy to jam.

Conveying form

Shaftless screw conveyor is suitable for: horizontal conveying, and the large inclination angle should not exceed 20°, according to the actual usage.

The shaft screw conveyor is suitable for: horizontal conveying, inclined conveying, and vertical conveying.

Conveying capacity

Due to the use of shaftless, the single-machine conveying length of the shaftless screw conveyor can reach 60 meters, and the conveying capacity is 1.5 times that of the traditional shafted screw conveyor with the same diameter

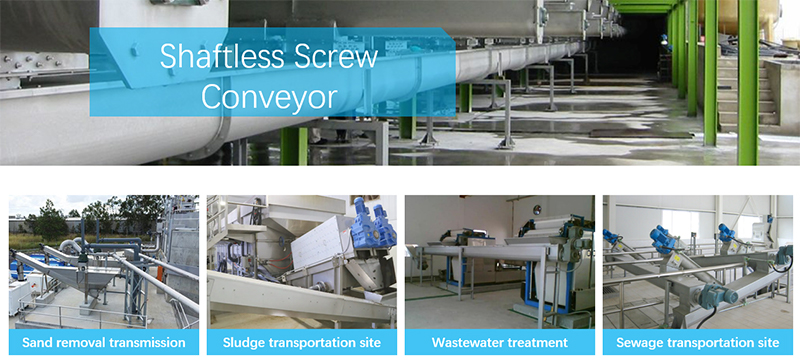

Shaftless Screw Conveyors Application

Shaftless Screw (Spiral) Conveyors are specially designed for handling difficult, heterogeneous materials such as urban solid waste, screenings and floating matter, de-watered, thickened, conditioned sludge, packaged food, creams or pastes, as well as waste from: meat, fish, fruit and vegetable processing. The main sectors of application are: wastewater treatment, sugarhouse rejects, fish industry, solid waste treatment, fruit and vegetable processing, beverage industry, pulp and paper, chemicals, food industry in general, meat processing plants, abattoirs/ slaughterhouses, restaurants, canteens, catering in general.

Name: Ashely Li

Mobile:+8613961861780

Tel:+8613961861780

Whatsapp:8613961861780

Email:info@dagyee.com

Add:Room 302, Building 11-4, Hongyi Road, Xinan Town, Xinwu District, jiangsu Province, China